Corrugated board - the stuff packaging is made of

Have you ever dreamed of waves? Our packaging experts at Model often do. Not of rushing masses of water in a warm holiday destination - but of flowing paper that combines in several layers to form incredibly stable corrugated cardboard.

To help you get to know the raw material corrugated board better, we have collected our concentrated expert knowledge for you. Read here:

- Flute types and their advantages

- flute combinations

- the technical values of corrugated board

- the secrets of different types of corrugated cardboard

You probably use the fascinating material corrugated cardboard almost every day. With your new corrugated cardboard knowledge, you are guaranteed to make good packaging decisions in future - for example when choosing your moving or shipping boxes.

Guide: All about corrugated board

The advantages of corrugated board

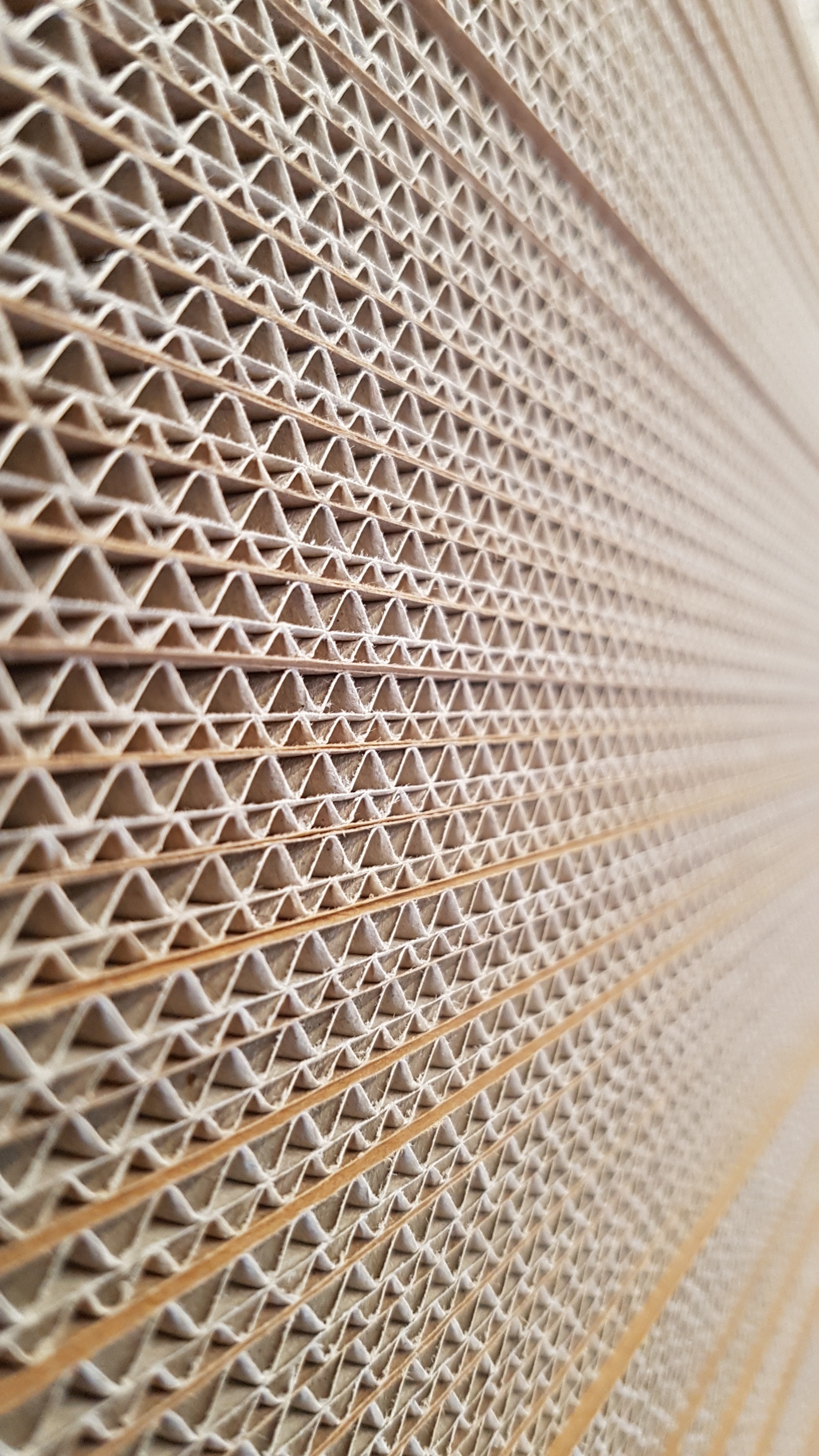

Paper, air, glue. These ingredients ensure the stable lightweight construction of corrugated cardboard. Several layers of corrugated paper are glued onto one or between several layers of another paper or cardboard.

Why is corrugated board so stable? This is due to the shape and arrangement of the corrugation. It cushions against external and internal loads, as the pressure is evenly distributed over the entire surface of the corrugated cardboard. This stable construction can also be found in nature, for example in wasps' nests.

Corrugated board in detail

The technical values of corrugated board

What must a corrugated cardboard box be able to do? It must be stable with a low net weight, it should be inexpensive, stackable and easy to use. DIN 55468 defines three specific quality characteristics for corrugated cardboard as a packaging material:

- the bursting strength in kPa (kilopascals)

- the puncture energy in joules

- the edge crush resistance in kN/m (kilonewton metres)

Corrugated board: The secret of the right grade

How do you find the right corrugated cardboard for your application? When making your choice, always consider the size and weight of your packaged goods and the shipping route. This results in

- a specific flute combination (two or three flute types can be combined to give the corrugated board specific properties),

- a specific grammage and the type of base paper (for example, the particularly robust Kraftliner paper grade or the more favourable Testliner paper grade as the cover paper and semi-pulp for the flute),

- a specific packaging design for the stability of the packaging and the protection of your product.

The FEFCO code for a better overview

The FEFCO code makes it easier for you to keep track of the designs of standardised shipping packaging. This is because all standardised corrugated cardboard boxes have an internationally used code that simplifies communication between manufacturers, retailers and consumers. Read detailed information about the FEFCO code here.

To help you find your way around the Model Online Shop quickly, we have catalogued our extensive range of standard corrugated cardboard boxes according to the FEFCO code. Simply enter your desired FEFCO number in the search box.

It all depends on the manufacturer

In addition to standard boxes, companies in the corrugated board industry offer their own optimised grades and individual designs, which are developed together with customers, for example.

At Model, we have been optimising corrugated cardboard and packaging since 1882 and have placed great value on the highest quality made in Switzerland since our company was founded. Thanks to our modern machinery and extensive expertise, you can order high-quality corrugated cardboard packaging directly from the manufacturer here in our online shop. Naturally with the best value for money.

We also make no compromises when it comes to sustainability. It is anchored in our DNA, because recycled cardboard and paper are the raw materials for our corrugated cardboard products.